The Customer

A leading US-based company in the international food display products industry was on the lookout for a vendor who could provide mechanical design services and also manage the customization process of their products for their different clients in other countries. Besides, the vendor was also required to re-design products for manufacturing and create drawings for prototyping. The customer wanted the design services delivered at a very fast pace because the customer faced an increase in sales.

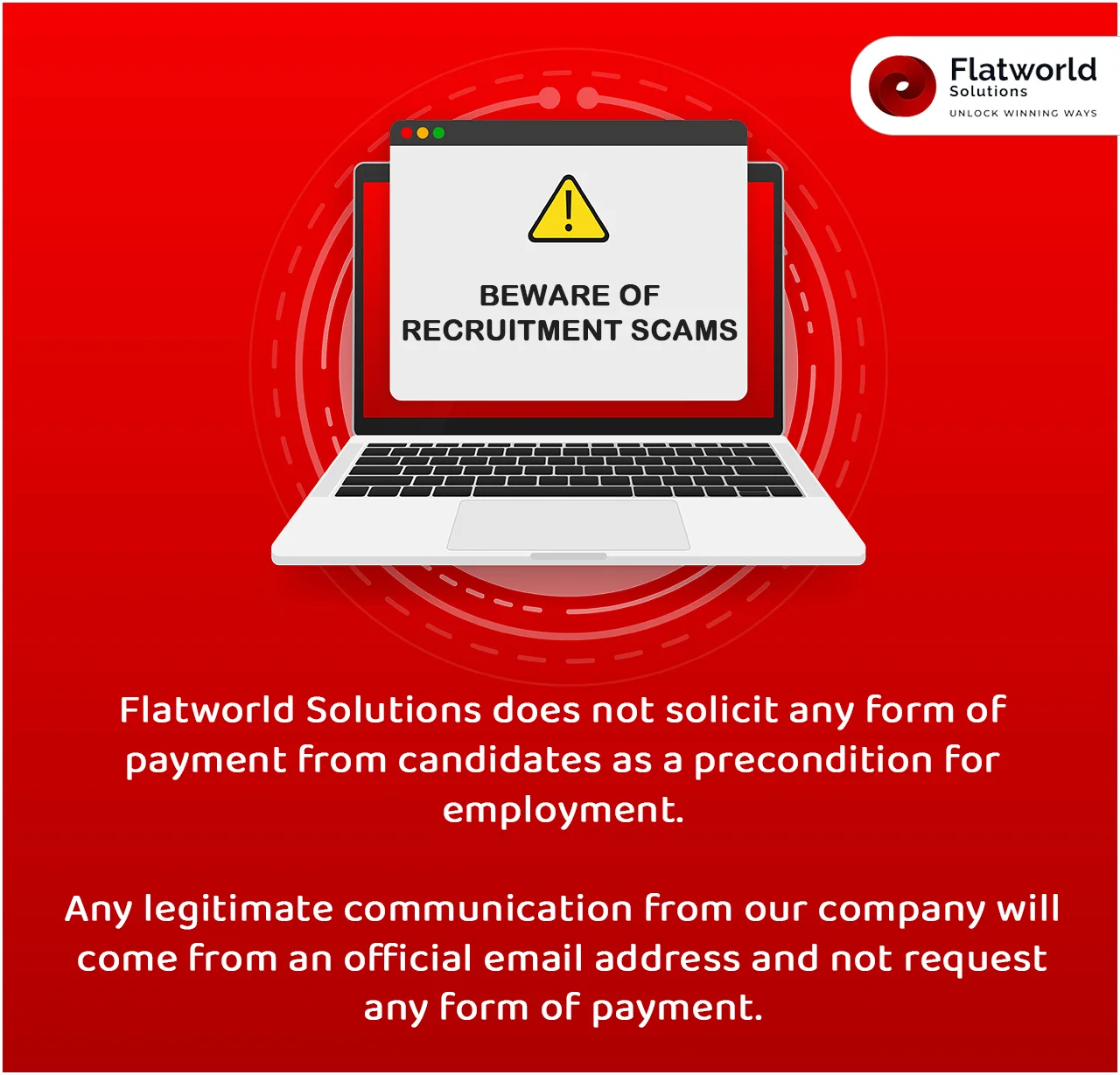

The Challenge

Experienced engineers were required to provide accurate design solutions within a quick turnaround time. To ensure that the deliveries were flawless, Flatworld's engineers would have to learn more about the customer's manufacturing equipment and understand the process thoroughly. However, being an offshore team of engineers, they could not physically see and understand the customer's manufacturing equipment and process. At the same time, they also had to ensure that prototyping iterations were minimized.

The Solution

The Flatworld team of trained engineers learnt and understood the customer's manufacturing process through the guidelines for design and manufacturing sent across by the customer. Technology came to the team's rescue in the form of tele-conferences, emails and web-conferences. This enabled the team to completely understand the systems, processes and the functionality of the product. To make the delivery mechanism robust, Flatworld's team of engineers introduced various quality checks within the process to keep a check on defects. Product training was imparted via the Internet through a secure gateway. Besides, a continuous monitoring of quality was carried out by using computerized programs.

The Results

Flatworld Solutions' team of experienced engineers successfully executed ten projects within ten months. Initially, innumerable iterations and quality checks were done to arrive at the right design. Over a period of time, the customer agreed that the first stage of every delivery would have iterations and quality checks. This resulted in achieving an accuracy rate of almost 99%.

Flatworld's continuous improvement program, which involves several quality checks, prevented many errors from being passed onto the customer. With Flatworld's services, the customer was able to meet crucial deadlines, manage designs in a better way and effortlessly launch products into the market. The customer recorded a savings of $60,000 by partnering with Flatworld Solutions.

The satisfied customer requested Flatworld to provide assistance in other value added areas, like BOM implementation by using the MRP software at the customer's location (through a secured inter-network connection) and PDM processes. Besides, the customer also requested Flatworld to provide finance and accounting services.

Flatworld Solutions' engineers now also create conceptual ideas and functional prototypes for new product development. They have a practical knowledge of high quality standards, procedures and processes relative to mechanical design engineering and the manufacturing of electro-mechanical products. This customer approached Flatworld for benefits such as lesser costs, but preferred to continue using Flatworld's services because of the quality of the services rendered. The customer also benefited from Flatworld's capabilities to scale-up their manpower and deliveries effortlessly.

Contact us to outsource mechanical engineering design services to Flatworld Solutions.

Contact UsAvail best-in-class services at affordable rates

Our Customers

Key Differentiators

Case Studies

-

Flatworld Solutions provided customized CNC programming using MasterCAM

-

Flatworld Provided CFD Simulation Services to a Leading HVAC Products Manufacturer

-

Flatworld Solutions Offered Mechanical Instrument Drafting and Detailing Services to an Engineering Consultant

-

Flatworld Solutions Offered US Client with 2D to 3D Mechanical Legacy Drawing Conversion

-

Flatworld Solutions Provided Reverse Engineering of Machine Parts to a Client

Join the growth phase at Flatworld Solutions as a Partner

Service distributorship and Marketing partner roles are available in select countries. If you have a local sales team or are a person of influence in key areas of outsourcing, it's time to engage fruitfully to ensure long term financial benefits. Currently business partnerships are open for Photo Editing, Graphic Design, Desktop Publishing, 2D and 3D Animation, Video Editing, CAD Engineering Design and Virtual Walkthroughs.

Reach out to us for a quick direct response from decision makers at the Flatworld Solutions global team.

USA

Flatworld Solutions

116 Village Blvd, Suite 200, Princeton, NJ 08540

PHILIPPINES

Aeon Towers, J.P. Laurel Avenue, Bajada, Davao 8000

KSS Building, Buhangin Road Cor Olive Street, Davao City 8000

INDIA

Survey No.11, 3rd Floor, Indraprastha, Gubbi Cross, 81,

Hennur Bagalur Main Rd, Kuvempu Layout, Kothanur, Bengaluru, Karnataka 560077