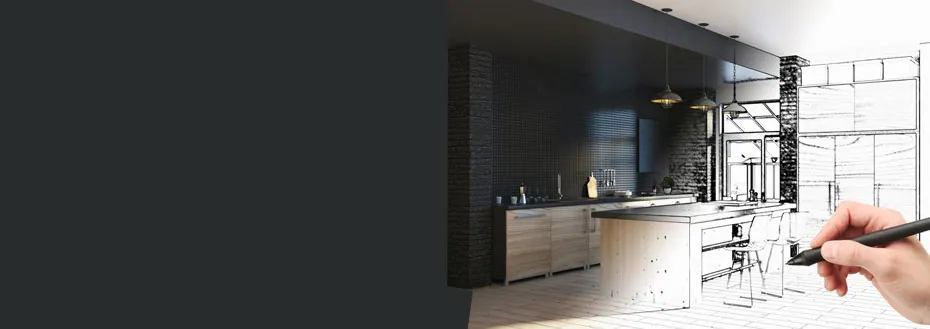

As a provider of engineering services for the kitchen equipment manufacturing industry, we specialize in addressing the industry's flow, function, and budgetary challenges. We facilitate product development by assisting in conceptualization, design, and rapid prototyping. We offer comprehensive design support, including 2D files, spec sheets, and CAD drawings. This empowers manufacturers to create well-conceived ergonomic and energy-efficient designs that translate into functional kitchen setups. With a focus on reducing time-to-market and enhancing innovation and aesthetics, we empower manufacturers to create high-quality kitchen equipment that's both efficient and visually appealing.

Our CAD models help optimize efficiency, reduce costs, and ensure compliance with safety standards. These models facilitate customization and quick adaptation to meet market demands. Whether you're a startup with limited resources or an established industry leader, we adapt our CAD solutions to fit your specific production requirements and budget constraints. Our scalable services cater to manufacturers of all sizes, making us a reliable partner in the pursuit of culinary excellence.

We have certified professionals working from global delivery centers to ensure faster response times and shorter downtime for kitchen equipment design. Such a setup translates to professional CAD offshore engineering for commercial kitchen planning and designs that combine local expertise with an international presence.

Harness our engineering design support for industrial kitchen equipment manufacturers to benefit from creative and flexible plans that drive your design success.

Services We Offer

Kitchen equipment design demands precision, innovation, and a keen understanding of industry dynamics. Our team of experts is adept at offering engineering design support that harmoniously blends functionality with aesthetics. We follow design approaches that focus on durability and cost efficiency. Take a moment to browse our diverse range of services, each meticulously crafted to propel your designs to new heights.

Product Design

We can help you to design kitchen equipment that is both functional and aesthetically pleasing. We will take into account your specific needs and requirements, as well as the latest trends and technologies in the kitchen equipment market. For example, we can use CAD software to create 2D and 3D models of your kitchen equipment to assess the functionality and design before it is manufactured. We can also use CAD to simulate the use of your kitchen equipment to ensure that it is ergonomic and user-friendly.

CAD Drafting

We offer CAD drafting services that deliver meticulous and comprehensive technical illustrations. These detailed depictions contribute to streamlining manufacturing processes, minimizing inaccuracies, and speeding up product realization, thereby keeping your project on schedule and within cost parameters.

3D Modeling

Utilizing 3D modeling, we transform kitchen equipment designs into tangible, lifelike visualizations. This allows for an easier appraisal and amendment of designs, promoting effective design communication and informed decision-making.

Manufacturing Process Optimization

Our expertise lies in analyzing and refining your manufacturing design processes to bolster efficiency and output. By curtailing waste, shortening cycle times, and enhancing workflows, we improve product quality while lowering production expenses.

Technical Documentation

Our technical documentation offering ensures your product designs are supported by clear, concise, and in-depth guides. This boosts customer comprehension, simplifies product operation and maintenance, and ultimately elevates customer satisfaction.

Assembly Design

We excel in assembly design, guaranteeing seamless integration of your product components. This amplifies the product's functionality and curtails assembly duration and costs, improving overall manufacturing effectiveness.

Sheet Metal Design

Our sheet metal design solutions aim to optimize designs for production and assembly. We strive to deliver efficient, cost-effective designs that diminish material wastage and production duration while augmenting product resilience and performance.

Product Lifecycle Management (PLM)

We oversee equipment design from conception to blueprint. This service facilitates process streamlining and time reduction in design, expediting product development. Our PLM solutions ensure a consistent and coordinated approach to managing product design modifications, boosting your profitability and brand esteem.

Design Validation

We authenticate your designs against defined criteria, confirming they satisfy all functional and performance expectations. This mitigates the risk of product failures and recalls, guaranteeing customer satisfaction and safeguarding your brand reputation.

Bill of Materials (BOM)

We deliver precise, comprehensive BOMs, enumerating all materials and components necessary for your equipment. This service enables efficient procurement and production processes, minimizing potential mistakes and production hold-ups and enhancing operational efficiency.

Design for Manufacturing (DFM)

Our DFM solutions ensure your product designs are highly functional and easy to manufacture. We harmonize aesthetic and functional factors with production expenses, diminishing manufacturing complexities and facilitating a hassle-free transition from design to production.

Plans and Layout Design for the Kitchen Equipment

Commercial Refurb

Ventilation and Extraction

Hygiene Systems

Refrigeration Equipment

Kitchen Design

Waste Management Systems

Design Process We Follow

Receiving and Reviewing Design Inputs

This includes accessing the client's initial designs and reviewing each element to understand the desired outcomes and specifications.

Design Refinement and Optimization

Our team then harnesses their expertise to refine and optimize these designs, enhancing functionality and aesthetics while ensuring manufacturability.

Comprehensive Quality Check

Every revised design undergoes a rigorous quality check, guaranteeing it meets all necessary parameters, standards, and client expectations.

Delivery and Client Collaboration

The finalized designs are sent back to the client, ready for implementation. We believe in an iterative process and welcome feedback, ensuring our designs fully align with our client's vision.

Discover What Makes Our Kitchen Equipment Design Company Stand Out

We take a holistic approach to design, considering factors such as functionality, durability, and efficiency. Our team of industry experts combines their deep knowledge with the latest technological advancements to create innovative design solutions. What truly distinguishes us is our emphasis on energy-efficient designs. We prioritize the use of sustainable materials and incorporate energy-saving features, helping our clients reduce their environmental footprint and operating costs. Following are some of the factors that set us apart -

Excellence Without Compromise

Our dedicated team ensures that every aspect of your kitchen equipment design meets and exceeds industry standards in terms of functionality, aesthetics, durability, and customer satisfaction.

Confidentiality at its Finest

We prioritize the security of your intellectual property and sensitive data throughout the design process. With robust security measures, including encryption, secure data storage, and strict access controls, we ensure your information remains confidential and protected.

Decades of Engineering Design Mastery

With over 20 years of experience assisting commercial manufacturers with equipment design projects, our team has honed their skills to create functional kitchen equipment designs using advanced tools.

Customized Solutions for Unique Design Needs

Our surveyors and designers work closely with you to strengthen your designs and plans, mitigating potential installation-phase issues. This personalized approach ensures that your kitchen equipment design aligns perfectly with your vision and operational requirements.

Innovation for Sustainability

Incorporating advanced technologies and energy-saving features, our designs enable you to run a sustainable business while reducing environmental impact. Our forward-thinking design estimations meet current industry standards and anticipate market needs for enhanced performance and sustainability.

Optimized Returns

We offer competitive pricing for our design services, striving to maximize the value of your investment. Our transparent pricing structure and flexible options provide exceptional design solutions that deliver the best return on your investment.

Additional Services We Offer

Get value-added services that help you visualize designs before production, identify potential issues, and make informed decisions.

Save time and effort by easily modifying and updating your designs, promoting efficient collaboration and reducing the risk of errors during manufacturing.

CAD Migration

Switch CAD systems or collaborate with partners who use different CAD platforms. We help you eliminate compatibility issues and enhance workflow efficiency.

Get precise drafting, rendering, and modeling solutions to ensure accurate manufacturing specifications, reduce errors, and optimize production processes.

Outsource Engineering Services for Kitchen Equipment Manufacturers

Staying ahead of the curve can get tricky in the dynamic realm of kitchen equipment design. Outsourcing your engineering design needs to professionals like us gives you access to technical expertise and advanced tools without added expenses. Our commitment to excellence and quality is evident in our engineering design and validation for institutional kitchen equipment manufacturers.

We offer a comprehensive range of services, allowing you to streamline your operations and tackle design challenges head-on. The result? Cost-efficient and energy-saving designs that adhere to both local and international standards. Working across multiple time zones, our team minimizes downtime for equipment design, directly impacting your bottom line.

Try our customized design support now to navigate the complexities of the design process and strengthen your market position. Let us redefine kitchen equipment design together.

Avail best-in-class services at affordable rates

Our Customers

Key Differentiators

Case Studies

-

Flatworld Solutions provided customized CNC programming using MasterCAM

-

Flatworld Provided CFD Simulation Services to a Leading HVAC Products Manufacturer

-

Flatworld Solutions Offered Mechanical Instrument Drafting and Detailing Services to an Engineering Consultant

-

Flatworld Solutions Offered US Client with 2D to 3D Mechanical Legacy Drawing Conversion

-

Flatworld Solutions Provided Reverse Engineering of Machine Parts to a Client

Join the growth phase at Flatworld Solutions as a Partner

Service distributorship and Marketing partner roles are available in select countries. If you have a local sales team or are a person of influence in key areas of outsourcing, it's time to engage fruitfully to ensure long term financial benefits. Currently business partnerships are open for Photo Editing, Graphic Design, Desktop Publishing, 2D and 3D Animation, Video Editing, CAD Engineering Design and Virtual Walkthroughs.

Reach out to us for a quick direct response from decision makers at the Flatworld Solutions global team.

USA

Flatworld Solutions

116 Village Blvd, Suite 200, Princeton, NJ 08540

PHILIPPINES

Aeon Towers, J.P. Laurel Avenue, Bajada, Davao 8000

KSS Building, Buhangin Road Cor Olive Street, Davao City 8000

INDIA

Survey No.11, 3rd Floor, Indraprastha, Gubbi Cross, 81,

Hennur Bagalur Main Rd, Kuvempu Layout, Kothanur, Bengaluru, Karnataka 560077