Are you burdened with the need to optimize existing resources and building capabilities while ensuring better cost savings? Is your requirement for improved performance leading to the demand for improved machinery? Jigs and fixtures are important parts of the manufacturing and production processes and are required to be designed with extreme accuracy and precision.

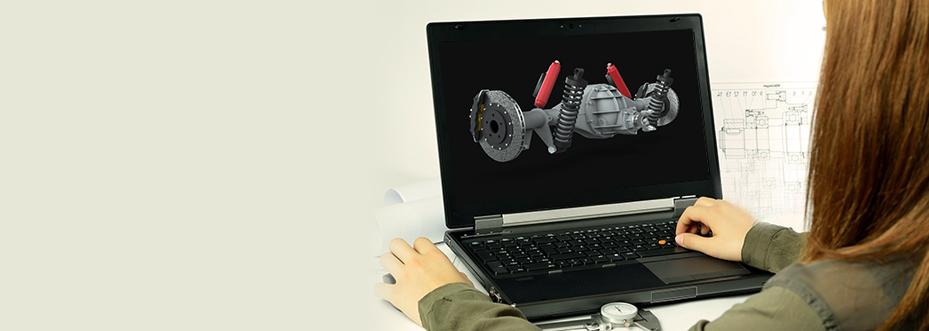

Our reliable jigs and fixture design services leverage feature-based modeling which allows us to simulate applications and visually analyze the entire production process. This along with our assembly design aids are directly responsible for high-quality fixture designs which suit the geometry of your workpieces.

Jigs and Fixture Design Services We Offer

Our engineers have the technical proficiency in using a wide array of CAD software packages which include AutoCAD, SolidWorks, SolidEdge software, Pro-Engineer, etc. This ensures they can deliver on the toughest jigs and fixture designing projects while working to your standards, specifications, and other requirements. Over the years we have worked with clients belonging to industries such as oil and gas, automotive, textile, manufacturing, aerospace, healthcare, etc. Our jigs and fixture design services include

2D/3D Visualization of Mechanical Parts

Assembly Fixtures Design

Billing of Materials

Cost Estimation

Boring and Drilling Jigs

Checking Fixtures and Gauges

Industry Compliance

Creation of 2D Drawings

Hydraulic and Pneumatic fixtures

Open and Closed Jigs

Preparing Process Sheets

Quality Checks

Testing Fixtures

Verifying Data Sheet Specifications

Welding and Machining Fixtures

Woodworking Jigs and Framing Jigs

Form and Press Fixtures

Fixture and Tooling Reduction Solutions

Jigs And Fixture Design Process We Follow

We are one of the very few fixture design companies who have worked with clients across the globe and understand international specifications. Our team of design engineers will fulfill all your requirements while using a standardized step-by-step approach which ensures the highest quality deliverable. Our process includes the following steps

Requirement Gathering

We hold preliminary talks with your representatives to understand the nature of the requirement and how we can design the jigs and fixtures that suit your needs

Drafting

During this stage the jigs and fixture design and drafting take place. We ensure we keep all the specifications in mind so that the drafting is exactly as you require

3D Visualization

Once the 2D drafts are ready we create a 3D visualization for the client so they can have a look at the different mechanical parts while blowing the design up and checking how it functions with the remaining parts

QC Testing

We perform an in-depth qualitative analysis of the fixture design so as to ensure all the requirements are checked off before delivery. If required, we also work on the cost estimates, fabrication details, and the bill of materials

Delivery

Once we are satisfied internally with the output we send it over to the client through our secure FTP servers

Other Services You Can Benefit From

Why Outsource Jigs and Fixture Design Services to Flatworld Solutions?

As an established jig and fixture design service providing company, we believe our design optimizations over the years help to maintain focus on the basics while ensuring the final solution saves time and money while retaining accuracy and repeatability. Efficient tooling and fixture design is the key to gaining significant productivity gains, and we help you to achieve these goals while ensuring timely delivery of service every time. By partnering with us you stand to benefit from the following

ISO Certified Jigs and Fixture Design Services Provider

Our proficient team of fixture design engineers supports your concepts right from conceptualization to completion. Our process expertise has earned us ISO 9001 certification.

100% Compliance with Data Security

We understand that with clients around the world working to different specifications, each project works independently and with requirements which exactly meet your specifications. We data management policies comply with the ISO/IEC 27001:2022 guidelines to ensure confidentiality and privacy to your project and data.

Best-in-class Quality Control

Our high-quality processes ensure the authenticity of the jigs and fixture design while ensuring all changes requested by you are incorporated easily.

Rapid Prototyping using Best Tools and Infrastructure

We can help you perform simulated prototyping for complicated jigs and fixtures for better understanding by leveraging our state-of-the-art technologies and infrastructure.

Affordable Pricing

Our pricing structure is extremely dynamic and changes from region to region, ensuring it always suits your budget no matter which country you might be from.

Infinitely Scalable

Our innate ability to handle multiple design requests and work around different client requests makes us one of the most flexible fixture design companies out there.

Rapid TAT

We deliver the project on or before time in 99% of the projects we work on, making us a trusted engineering service provider.

SPOC

We provide a full-time manager who will be in charge of attending your calls and messages through email. Our SPOC will swiftly resolve your concerns if any. They are highly available so that you can skip the queue and other hassles to reach a human operator.

Proficient Team

Our team consists of experienced draftsmen and fixture design engineers hired from top engineering institutes and universities, ensuring only the best employees work on your project.

Round-the-clock Validation

Our processes are set up in such a way that we are constantly validating and systemizing the fixture design for our clients to best results.

All-round Support

With our streamlined processes and an exhaustive list of specialist engineers, we can help bring down production costs with our efficient designs which are a direct result of our efficient design structure. Get support anytime, anywhere by just pining us or calling our contact center.

Outsource Jigs and Fixture Design Services to FWS

At Flatworld Solutions, we work with an experienced team of designers who are proficient in designing and creating both simple as well as complicated jigs and fixture designs. With years of experience in mechanical engineering services under our belts, we have the requisite expertise to offer distinguished jigs and fixture design and drafting services. We can create high-end jigs that can control the motion as well as the location of another tool. Our fixtures, on the other hand, serve as perfect holding devices for the rest of the tool or machinery. With the help of CAD prototyping, our designers collaborate with each other to constantly work on your needs and design parts based on your specifications. Not only are the designs created by us ANSI-compliant and ISO-certified but our guarantee of high-quality, peerless design and faster production ensures our clients always return to us for their requirements.

To know more about our services, contact us right away!

Contact UsAvail best-in-class services at affordable rates

Our Customers

Key Differentiators

Case Studies

-

Flatworld Solutions provided customized CNC programming using MasterCAM

-

Flatworld Provided CFD Simulation Services to a Leading HVAC Products Manufacturer

-

Flatworld Solutions Offered Mechanical Instrument Drafting and Detailing Services to an Engineering Consultant

-

Flatworld Solutions Offered US Client with 2D to 3D Mechanical Legacy Drawing Conversion

-

Flatworld Solutions Provided Reverse Engineering of Machine Parts to a Client

Join the growth phase at Flatworld Solutions as a Partner

Service distributorship and Marketing partner roles are available in select countries. If you have a local sales team or are a person of influence in key areas of outsourcing, it's time to engage fruitfully to ensure long term financial benefits. Currently business partnerships are open for Photo Editing, Graphic Design, Desktop Publishing, 2D and 3D Animation, Video Editing, CAD Engineering Design and Virtual Walkthroughs.

Reach out to us for a quick direct response from decision makers at the Flatworld Solutions global team.

USA

Flatworld Solutions

116 Village Blvd, Suite 200, Princeton, NJ 08540

PHILIPPINES

Aeon Towers, J.P. Laurel Avenue, Bajada, Davao 8000

KSS Building, Buhangin Road Cor Olive Street, Davao City 8000

INDIA

Survey No.11, 3rd Floor, Indraprastha, Gubbi Cross, 81,

Hennur Bagalur Main Rd, Kuvempu Layout, Kothanur, Bengaluru, Karnataka 560077