The Customer

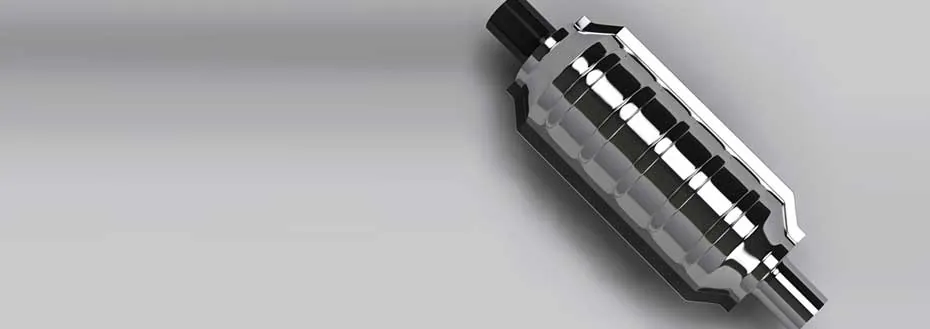

An engine catalyst company in the United Kingdom was looking for a partner to help them with their product development. This company developed catalytic converters, diesel filters, front pipes for automobiles, fitting kits, universal catalysts, performance catalysts, and much more, and needed assistance with the design of a catalytic converter.

The company sent two distinct catalytic converters to Flatworld Solutions via post, needing our staff to reverse engineer the devices, as well as take that information and map out a successful catalytic converter design.

The Challenge

The primary challenge related to the manifolds of the catalytic converter. The two samples that were sent to Flatworld used smaller manifolds than this company was hoping for their product. They needed larger manifolds, which had the potential to drastically alter the design.

Once completed, we found that the client also had an out of date version of SolidWorks, and was unable to open the design file.

The Solution

Using a full team of 8 FTE (full time equivalent) staff members exclusively assigned to the project, Flatworld Solutions successfully reverse engineered from the catalytic converter samples provided with the bigger manifolds, and was able to provide a fully functional catalytic converter at the specifications necessary to match the needs of the company. Our team laser scanned the components, extracted them into cloud point data, and gave the output in SolidWorks 2015.

When we found out that our design was unable to be viewed by their software (the client was running SolidWorks 2014) we then converted the document into .igs format, and the client was able to open it successfully.

The Results

Thanks to the experienced reverse engineers at Flatworld Solutions, we were successfully able to meet all of the client's benchmarks, not only in terms of the final product and delivery, but also in timeline. The entire process was completed in 45 days, giving the company ample time to bring their product to market.

The client was very pleased with Flatworld Solution's ability to match their deliverables, and send over 54 more catalytic converter samples for Flatworld Solutions to reverse engineer and design. Our company was able to help them design dozens of new products. The company originally contacted Flatworld to improve their efficiency, but ended up choosing us as a partner in their ongoing product development efforts.

If you're interested in finding out more about our reverse engineering services, or you'd like us to start on your next outsourced projects, please feel free and contact us today.

Contact UsAvail best-in-class services at affordable rates

Our Customers

Key Differentiators

Case Studies

-

Flatworld Solutions provided customized CNC programming using MasterCAM

-

Flatworld Provided CFD Simulation Services to a Leading HVAC Products Manufacturer

-

Flatworld Solutions Offered Mechanical Instrument Drafting and Detailing Services to an Engineering Consultant

-

Flatworld Solutions Offered US Client with 2D to 3D Mechanical Legacy Drawing Conversion

-

Flatworld Solutions Provided Reverse Engineering of Machine Parts to a Client

Join the growth phase at Flatworld Solutions as a Partner

Service distributorship and Marketing partner roles are available in select countries. If you have a local sales team or are a person of influence in key areas of outsourcing, it's time to engage fruitfully to ensure long term financial benefits. Currently business partnerships are open for Photo Editing, Graphic Design, Desktop Publishing, 2D and 3D Animation, Video Editing, CAD Engineering Design and Virtual Walkthroughs.

Reach out to us for a quick direct response from decision makers at the Flatworld Solutions global team.

USA

Flatworld Solutions

116 Village Blvd, Suite 200, Princeton, NJ 08540

PHILIPPINES

Aeon Towers, J.P. Laurel Avenue, Bajada, Davao 8000

KSS Building, Buhangin Road Cor Olive Street, Davao City 8000

INDIA

Survey No.11, 3rd Floor, Indraprastha, Gubbi Cross, 81,

Hennur Bagalur Main Rd, Kuvempu Layout, Kothanur, Bengaluru, Karnataka 560077